CREMAnufacture offers manufacturers a powerful platform for creating a digital view of the factory by transforming physical assets into IT services. All assets can be monitored in real time. Assets and people will interact with each other to drastically improve maintenance and production processes.

The age old issue of pulling information from the production plant will continue to dominate the requirements for manufacturing companies for the foreseeable future. The challenge is to be able to connect to multiple systems that may not be interoperable or to legacy systems with no obvious network connectivity options. CREMAnufacture can bring that connectivity from shop floor systems to the cloud with scalable technology. CREMAnufacture Software allows multipoint connectivity across the enterprise and ultimately provides the tools to be able to give decision makers visibility across their shop floor systems as well as collaboration tools to interact with customers and suppliers alike to maximise throughput and efficiency of the product. There are several optional packages available to suit specific manufacturing requirements and each of these are tailored to provide user-friendly software solutions for the manufacturing sector.

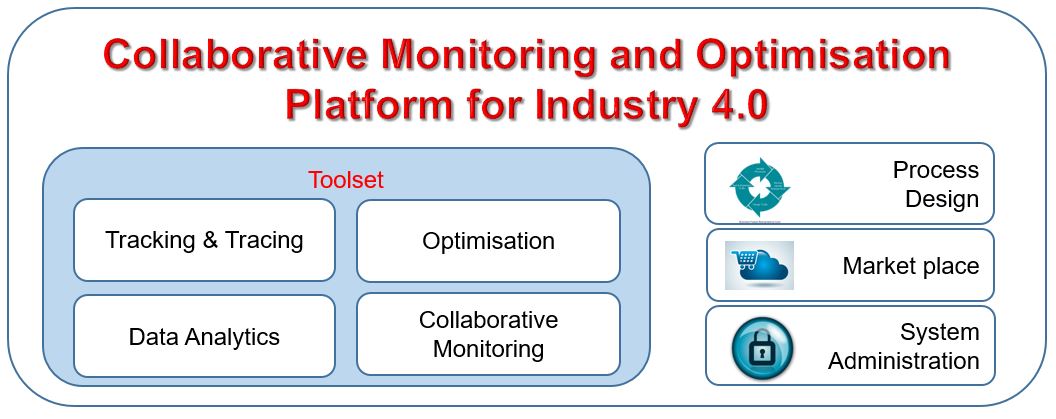

Our Platform

CREMAnufacture solution offers its customers an integrated platform for:

- Identifying, predicting and reducing production errors

- Accurate quality control

- Real time plant-floor and business-wide visibility

- Eliminating waste and inefficiency

Our Products

So far, we have four products in our toolset - these are expected to stir up the way that the Shop Floor personnel and the analysts are interacting with the different machines, robots and sensors that can be found in the production lines of any manufacturing company. With the Shop Floor Monitoring it is possible to have within the same screen a set of customised business rules capable of telling you if your production lines are well performing or if there are any problems. All sensors and machines will be constantly sending data to this tool, which will trigger the necessary alarms. The other tool, the Personal Collaboration, will help the production line operators when interacting with the robots or machines while they are carrying out any kind of maintenance activity. This is done with the help of Smart Glasses or Smart Gloves that will tell the operator the steps and guide him through his actuation.