Benefits of location intelligence in the industrial world

A standard to measure the manufacturing productivity is the Overall Equipment Effectiveness “OEE”, which defines the percentage of truly productive manufacturing time. This measurement is based on three indicators:

- Availability – it measures the non-stop time taking into account planned and unscheduled downtimes.

- Quality – It measures the good parts produced, considering defect parts.

- Process performance – it measures if the process is working as fast as possible, taking into account slow cycles and small stops.

In order to obtain the best results it is important to minimize as much as possible the factors that affect the OEE.

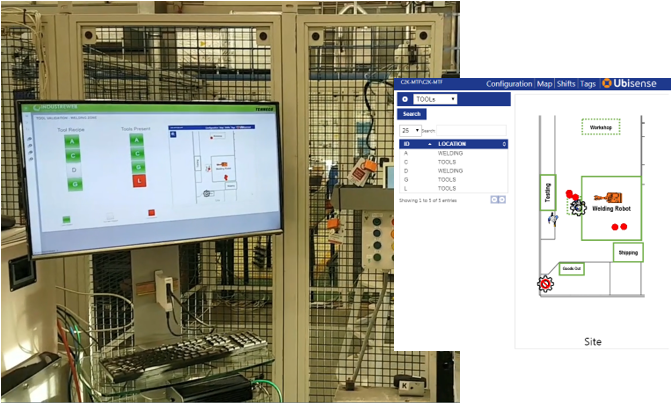

Due to the huge amount of processes and machines available in the factories sometimes it is difficult to find assets (tools, components, etc.), causing unexpected downtimes. The use of location intelligence provides the possibility to reduce and almost eliminate this times by installing sensors and tags in the assets of the manufacturing process. Making possible to see on a smart device the exact position of the asset required.

Other use of the location intelligence is the identification of assets mismatch. With this system it is possible to compare for instances the tool recipe of the required tool with the one of the tool that is going to be installed. In case of mismatch a real time alert will appear, avoiding the use of wrong tools, which usually results in big amounts of scrap parts.